Universal and compact

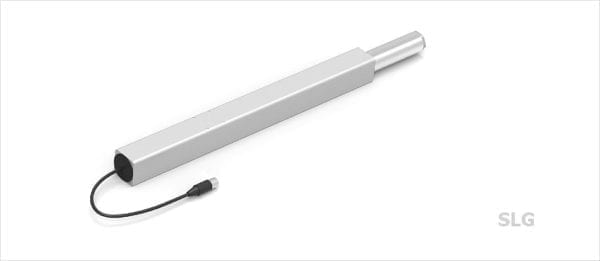

The housing of the linear unit consists of an anodized aluminum profile. The stand pipe is made of stainless steel and positioned in a plastic bushing. It is operated by means of an internal spindle drive. The cable length is 2 meters. Up to 4 linear units can be connected to one control unit and operated synchronously.

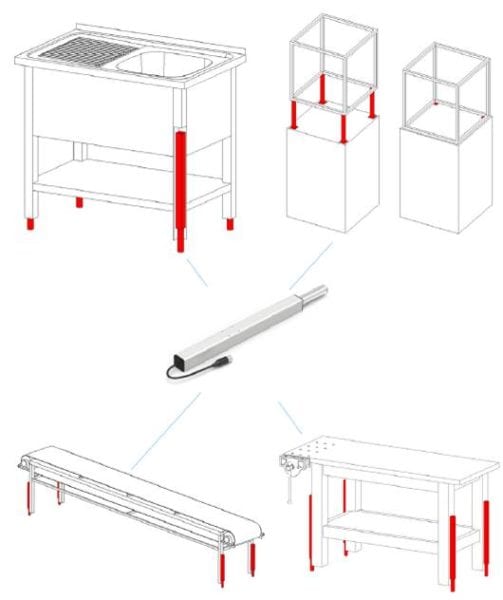

The linear units SLGare used in places where a work surface needs to be adjusted to the right ergonomic height. Compared to the linear unit SLA (cross section 35×35 mm), the linear unit SLG (cross section 45×45 mm) can absorb higher bending moments and is more stable at the same lifting distance.Existing work stations can simply be retrofitted. The systems also fit perfectly into the 50×50 mm steel profiles which are often used as support elements and legs for work stations.

Downloads

PDF DownloadOverview

- Stability: 3.5/5

- Cross Section: 45 x 45mm

- Installation: 600 mm - 700 mm

- Lifting Distance: 300mm - 400mm

- Hydraulic Lifting System: LG

- Max System Load (Hydraulic): 1500 N - 2500 N

- Spindle Lifting System: SLG

- Max System Load (Spindle): 1500 N

Technical Data

- Lifting Capacity: Max. lifting load per SLG - 1500 N

Max. pulling load per SLG - 1500 N

- Max. static bending moment: Mb = 250 Nm

- Max. dyn. bending moment: Mbdyn = 80 Nm

- Stroke length: Stroke length - 300 mm (11.8”) or 400 mm (15.74”)

SLG length A - 600 mm (23.62”) or 700 mm (27.56”)

Lifting System SQ - Plug & Play 1-4 SL per control box plus 1x hand switch

- Max Speed: 9 mm/s